Steel Plate Corrosion-Resistant Coating Experiment

Feb 21, 2024|

Feb 21, 2024| View:196

View:196With the development of the economy and the acceleration of industrialization, the application of metal products such as steel has significantly increased. However, this has also led to exacerbated corrosion issues. Corrosion can cause substantial damage to steel products, shorten their lifespan, and result in significant losses in production and daily life. Therefore, effective measures should be taken to prevent corrosion of steel.

In February 2024, Evergreen Chemicals successfully conducted an experiment on the production of corrosion resistant coatings for steel plates in its research and development laboratory. This experiment was led by engineers Li and Chen. The experiment adopted the "three fabrics, five coatings" process, which utilizes the physical and chemical properties of corrosion resistant materials to prevent corrosion on the surface of steel:

Three fabrics: Refers to the use of three layers of fiberglass cloth with different specifications for reinforcement when making fiberglass products. Typically, a thicker outer layer cloth, middle layer cloth, and finer inner layer cloth are used. This layout provides better strength and durability.

Five coatings: Refers to the process of applying vinyl resin five times on the basis of reinforcing fiberglass cloth. After each application of vinyl resin, appropriate curing treatment is performed to ensure a strong bond between the resin and the fibers. This forms a solid composite material structure.

The experiment proceeded in the following sequence:

1. Surface Treatment: Before applying the "three fabrics, five coatings" corrosion resistant construction, the surface of the steel plate was first treated by grinding. The purpose of this treatment is to remove impurities such as oil stains, rust, and oxides from the surface, making it smooth and clean for subsequent coating adhesion. Surface treatment methods include mechanical treatment, chemical treatment, and heat treatment.

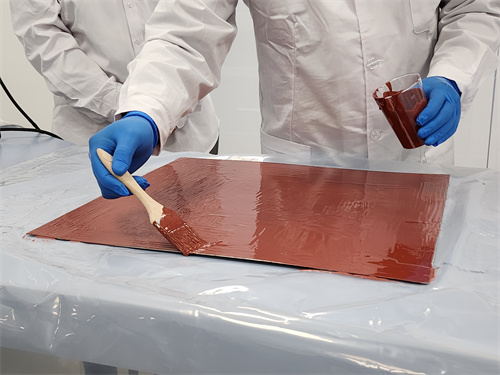

2. Primer Coating: The primer is the first layer of paint in the "three fabrics, five coatings" corrosion resistant construction, mainly used to enhance the adhesion and anticorrosive properties of the coating. The selection of primer should be based on the operating environment of the equipment and the requirements of the coating. Attention should be paid to the uniformity and thickness of the primer coating, with a generally required thickness between 50-100μm.

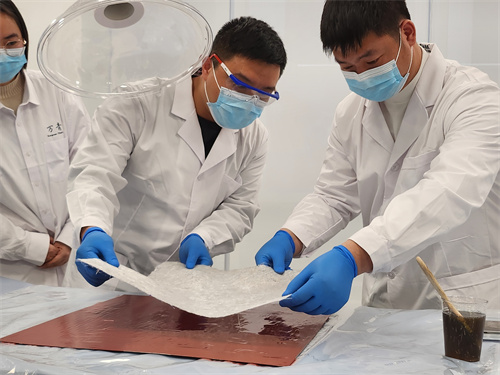

3. First Layer Fiberglass Cloth: The first layer of cloth is the first layer of fabric in the "three fabrics, five coatings" corrosion resistant construction, mainly used to fill surface irregularities and defects and enhance the adhesion and anticorrosive properties of the coating. The selection of the first layer of fabric should be based on the operating environment of the equipment and the requirements of the coating, with a generally required thickness between 100-150μm.

4. Second Layer Fiberglass Cloth: The second layer of cloth is the second layer of fabric in the "three fabrics, five coatings" corrosion resistant construction, mainly used to enhance the anticorrosive and abrasion resistance of the coating. The selection of the second layer of fabric should be based on the operating environment of the equipment and the requirements of the coating, with a generally required thickness between 150-200μm.

5. Third Layer Fiberglass Cloth: The third layer of cloth is the third layer of fabric in the "three fabrics, five coatings" corrosion resistant construction, mainly used to enhance the anticorrosive and abrasion resistance of the coating. The selection of the third layer of fabric should be based on the operating environment of the equipment and the requirements of the coating, with a generally required thickness between 200-250μm.

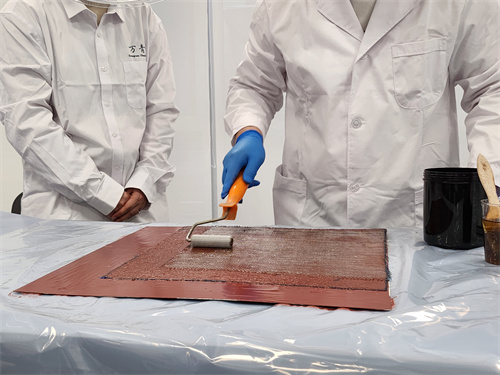

6. Intermediate Coating: The intermediate coating is the fourth layer of paint in the "three fabrics, five coatings" corrosion resistant construction with vinyl resin, mainly used to enhance the anticorrosive and abrasion resistance of the coating. The selection of the intermediate coating should be based on the operating environment of the equipment and the requirements of the coating, with a generally required thickness between 50-100μm.

7. Topcoat Coating: The topcoat is the final layer of paint in the "three fabrics, five coatings" corrosion resistant construction, mainly used to beautify the surface of the coating and enhance its weather resistance and abrasion resistance. The selection of the topcoat should be based on the operating environment of the equipment and the requirements of the coating. Attention should be paid to the uniformity and thickness of the topcoat coating, with a generally required thickness between 50-100μm.

Through this experiment, Evergreen Chemicals' research and development team continuously improved the production process of steel plate corrosion resistant coatings. These products will provide reliable protection for steel structures and equipment in the industrial field, improve their lifespan and durability, and provide reliable guarantee for industrial production.

Evergreen Chemicals will continue to focus on research and development innovation, continuously improve product quality and technical level, provide customers with higher quality chemical solutions, and contribute to the sustainable development and progress of the industrial field.