Application and Innovation of Vacuum Pouring Closed Mold Technology in Ship Structure Construction

Dec 26, 2023|

Dec 26, 2023| View:200

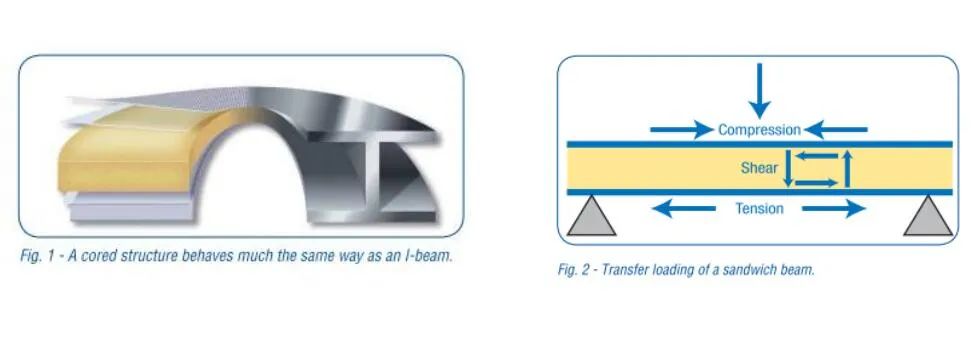

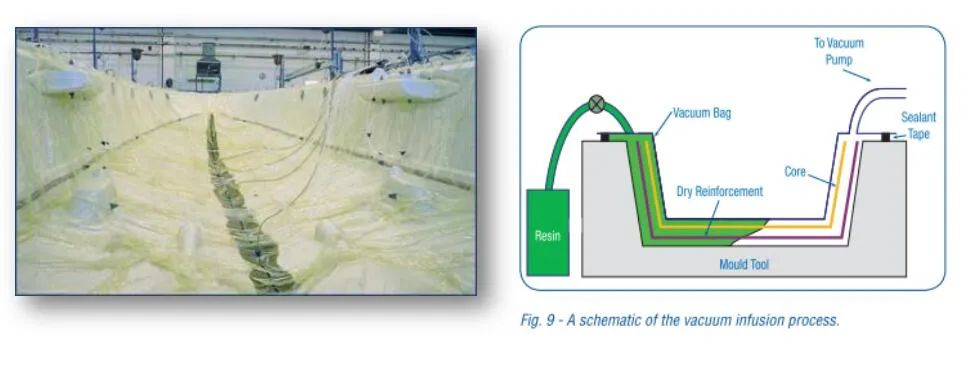

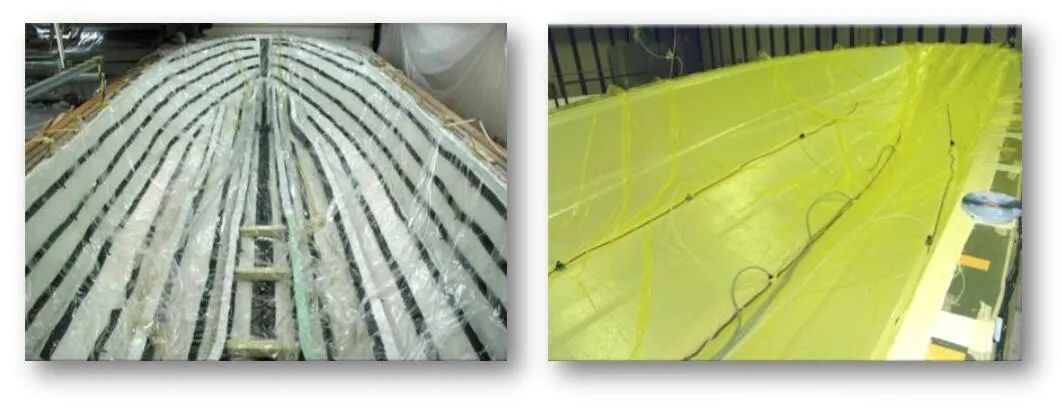

View:200Sandwich composite structure and vacuum infusion process

The vacuum injection molding process is rapidly being adopted by large and small composite material manufacturers throughout the industry

It integrates and enhances the advantages of composite materials, such as light weight, high specific strength and modulus, and reduces the instability of manual operations, ensuring higher quality stability of the product.

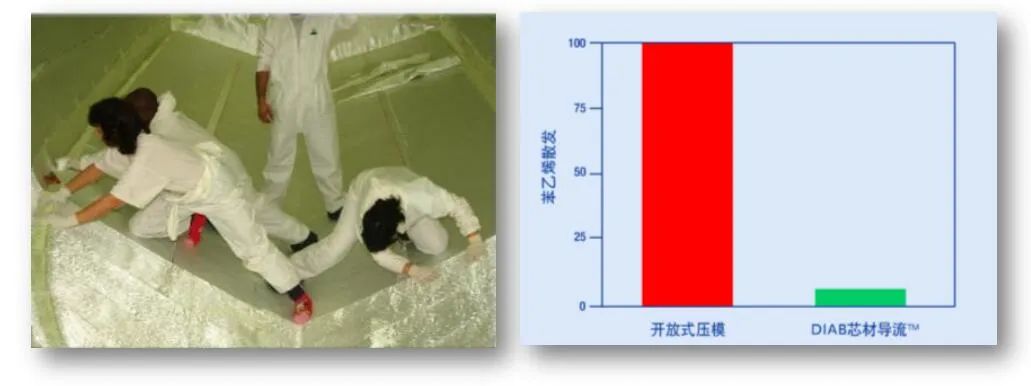

Health advantages: a more environmentally friendly and healthy working environment

Environmental advantages: Operators do not need to have direct contact with resin

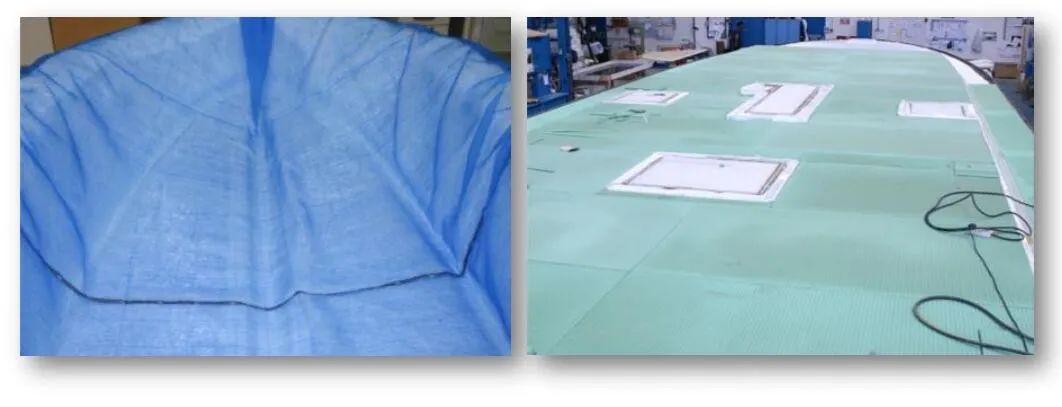

Production advantages: Can use existing molds, low investment, fast start-up

Cost advantage: By using specially treated core material surfaces, there is no need to use additional disposable flow guiding media (such as flow guiding nets and flow guiding felt). With a higher resin flow rate, the number of resin feeding pipes can be minimized. Compared with hand layup, this significantly reduces the mold cycle and labor costs.

Quality and performance advantages: Compared with hand layup, the fiber content has significantly increased, and the strength and stiffness performance of the layers have also been improved, while the weight has been reduced, and the interlayer adhesion is more firm.